How Flir Supports Quality & Safety Throughout EV Battery Assembly

Flir Total Solution for the EV Battery Industry

The electric vehicle (EV) industry is growing rapidly around the world, driven by a variety of factors, including government regulations, consumer demand for environmentally friendly transportation, and technological advancements that have made EVs more practical and affordable.

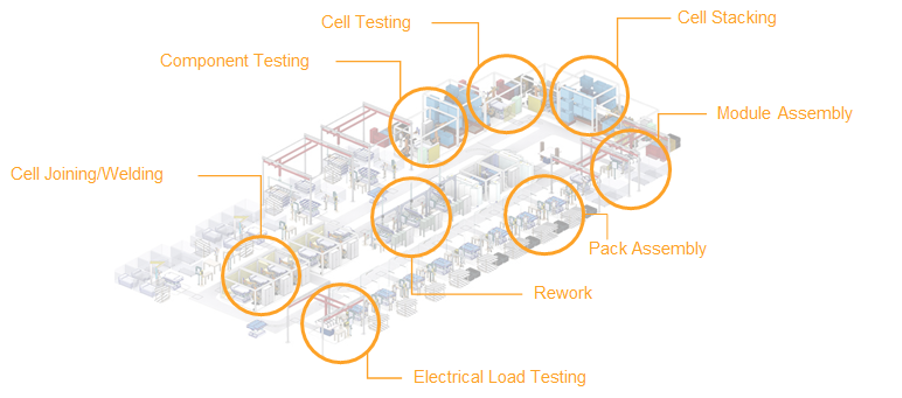

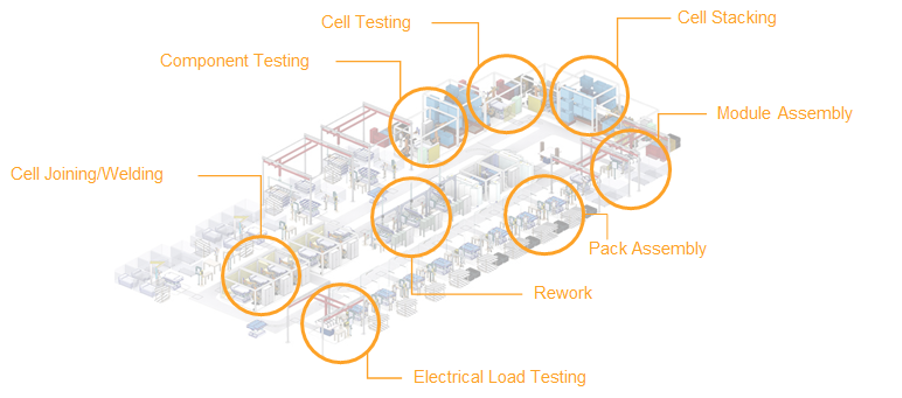

The whole industry chain consists of semi- and semi/fully-automated production lines that require smarter tools to keep pace. Long-term quality, product reliability, and worker and facility safety are also top priorities, particularly in battery production inspection.

Flir offers the total solution for improving EV battery quality, reliability, and safety through its line of thermal imaging cameras, automation sensors, and Test & Measurement products, specifically designed for battery thermal inspection.

Download our comprehensive look at applications and solutions across the EV battery industry.

Flir automated thermal cameras are a flexible, configurable solution to meet the needs of EV battery manufacturing. Our fixed-mount models can identify a higher number of potentially loose connections, significantly reducing end-of-line failures in battery systems. By integrating automated thermal cameras into production lines, manufacturers gain several advantages:

At Flir, we value our customers’ needs, which allows us to provide tailored solutions that empower them to meet their challenges with full force. Our passion for the advancement of technology in battery thermal testing signifies the trust, safety, and reliability that we have built over the years, creating together a sustainable future.

Equip your staff with battery inspection skills through infrared thermography training courses offered by the Infrared Training Center. We offer both online and onsite training courses for large groups and organizations in the EV battery manufacturing industry looking to improve their thermal inspection skills.

Get in touch with us to discover the best software for your cameras.