Flare stacks are used in many industries to burn off unwanted waste gas byproducts, or flammable gases released by pressure relief valves during unplanned over-pressuring of plant equipment. Thermal imaging cameras are ideal monitoring tools because they allow full-time remote monitoring in virtually any weather. In addition, thermal imaging cameras avoid many of the technical and cost-related problems associated with other technologies such as ultraviolet (UV) flame detectors, flame ionization spectrometers, thermocouples, and pyrometers.

Avoiding Breakdowns, Maximizing Uptime

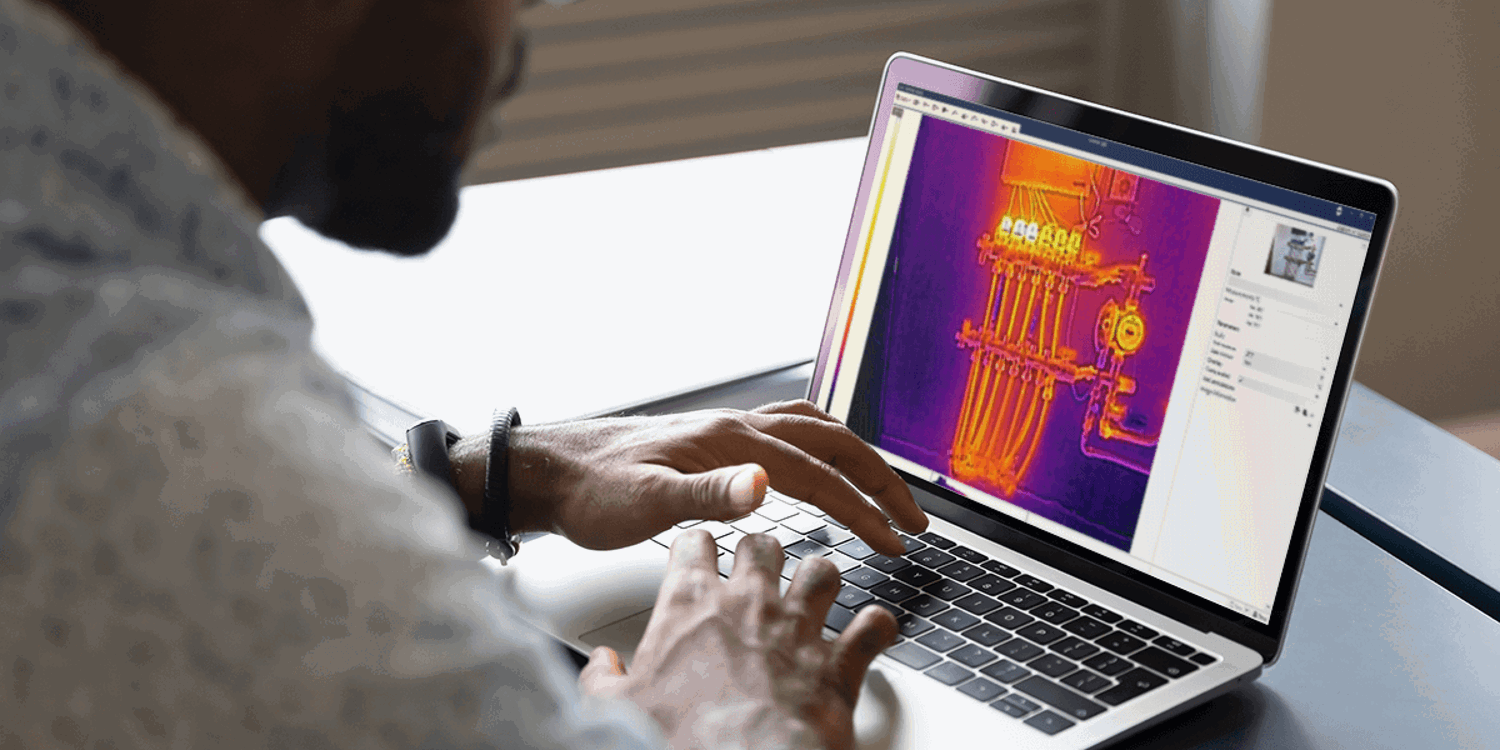

Continuous monitoring identifies problems before failures occur in order to prevent costly production stops. Typical equipment that is monitored includes high- and low-voltage installations, turbines, compressors, and other electrical and mechanical equipment.

Proper condition monitoring with continuous thermal cameras can be an efficient and effective way to maintain uptime. To learn more about condition monitoring, please visit this page.

Get the Automation & Industrial Safety Brochure

Configurable to meet your process/quality control needs

With FLIR A50 and A70 Series cameras, you can do everything from monitor thermal gradients in a volcano to verifying consistency across production lines.

Configurable to meet your process/quality control needs

World-Class Thermal Imaging and Seamleess Integration

Compact FLIR thermal imager is a game changer for condition monitoring

Ensuring Substation Uptime

Electric power utilities today are faced with an aging infrastructure, increasing risk of blackouts and brownouts as well as security threats. Unplanned maintenance can be expensive in the best-case scenarios and catastrophic in the worst. With FLIR thermal imaging cameras and condition monitoring software, impending equipment failures and security breaches can be detected anytime, day or night, from a remote monitoring location.

Avoiding Catastrophic Failure

Steel mill ladles have limited lives. As their refractory linings wear or break due to shock, the outer part of a ladle can be exposed to excessive temperatures. Flir thermal imaging camera systems can monitor ladles, catching disintegration and potentially preventing a molten metal breakout.

More on Steel Manufacturing

24/7 Electrical Installation Monitoring

Some critical electrical and mechanical installations in manufacturing companies and utilities are monitored 24/7 with a thermal imaging camera. Heat buildup indicates poor equipment health and possible impending failure. A fixed-mounted thermal imaging camera gives you the advantage, so you don’t need to rely on periodic inspections. Alarms can be set to go off once a temperature threshold is exceeded.

Get the Data for Your Analytics, Your Way

Detect and identify thermal issues across manufacturing and industrial processes, collect accurate thermal data, and analyze it using your own proprietary software with this new line of FLIR thermal imaging cameras. Axxx-Series cameras configured for Standard or Advanced Image Streaming can solve your specific task through simplified integration with custom developed software.

Give Your Customers Better Insight

For electric companies, professional reports go a long way toward helping your customers understand thermal camera inspections and the problems uncovered by our scanners. The advanced analysis and decision-making support offered in FLIR Thermal Studio Pro provides you with a rich set of measurement tools, batch processing, the ability to pre-plan inspection routes, and customized report templates.

Learn more about Thermal Studio

From the Discover Center