Acoustic Imaging for Food and Beverage Manufacturing

Save Energy Costs and Avoid Expensive Gas Leaks

Compressed air, vacuum systems, and food-grade carbon dioxide (CO2) are used in many production processes across the food and beverage industry. Undetected leaks can lead to serious consequences such as energy inefficiency, increased downtime for repairs, or loss of an important additive—the carbonation needed for soft drinks.

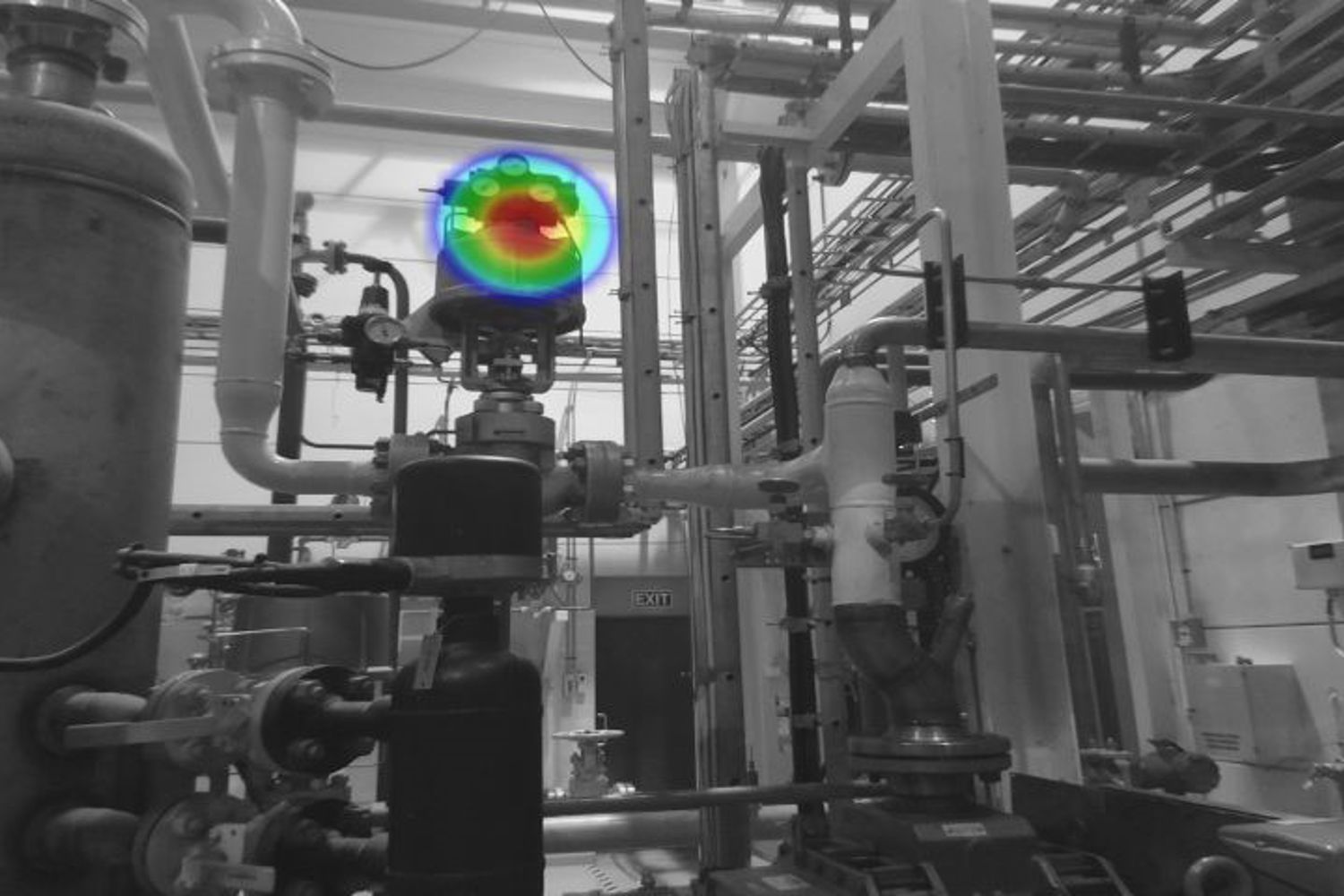

This is where an acoustic imaging camera can make all the difference. Thanks to 124 low-noise microphones, acoustic cameras such as the FLIR Si-Series help identify even very small leaks promptly, improving the system’s efficiency, reducing operating costs, and helping to maintain product quality.

With an acoustic camera you can:

- Proactively Detect Leaks: Identify even the most minute leaks that are inaudible in bustling factory environments.

- Maintain Operational Efficiency: Seamlessly integrate the camera into any maintenance phase without stopping production.

- Achieve Cost & Energy Savings: Get insights from AI-driven analytics on leak magnitude and associated cost implications.

- Drive Informed Repairs: Use real-time data to craft strategic maintenance and repair plans.

Minimize Gas Losses

If your food or beverage production process uses gas, then acoustic imaging can detect and report leaks, helping to reduce financial losses and lower the cost of doing business.

Use the Si-Series to detect:

- Carbon dioxide

- Oxygen

- Nitrogen

- and more

The gases used in various production processes represent a significant cost to business, so minimizing these leaks can make an immediate impact to the net profit at the end of the year.

FLIR Si-Series Acoustic Imaging Cameras for Compressed Air and Vacuum System Leak Detection

Ultrasonic imaging with an acoustic camera is an effective way to identify efficiency loss and potential failures up to 10 times faster than traditional methods—with minimal training.

Core Benefits of Acoustic Imaging:

- Reduced energy usage

- Reduced CO2 and other gas emissions

- Prolong compressor/vacuum pump life

FLIR Si-Series Advantages:

- No training required

- Concise reporting

- Leak quantification

- Background noise filtering

- Accurate measurement of leaks as small as 0.004 l/min from 1 m (3.0 ft)