Recorded Webinar: Steel process automation and optimization with thermal monitoring

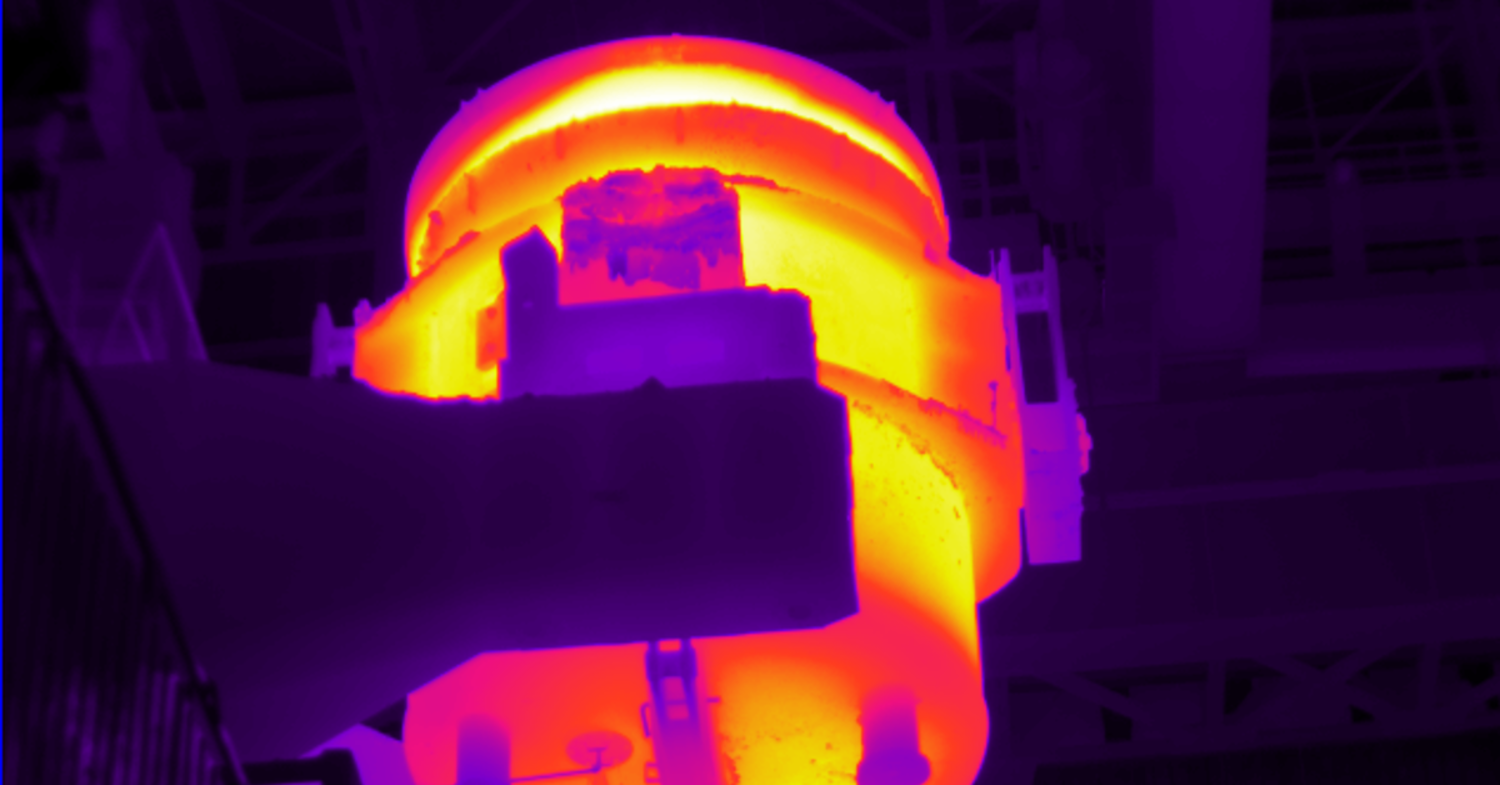

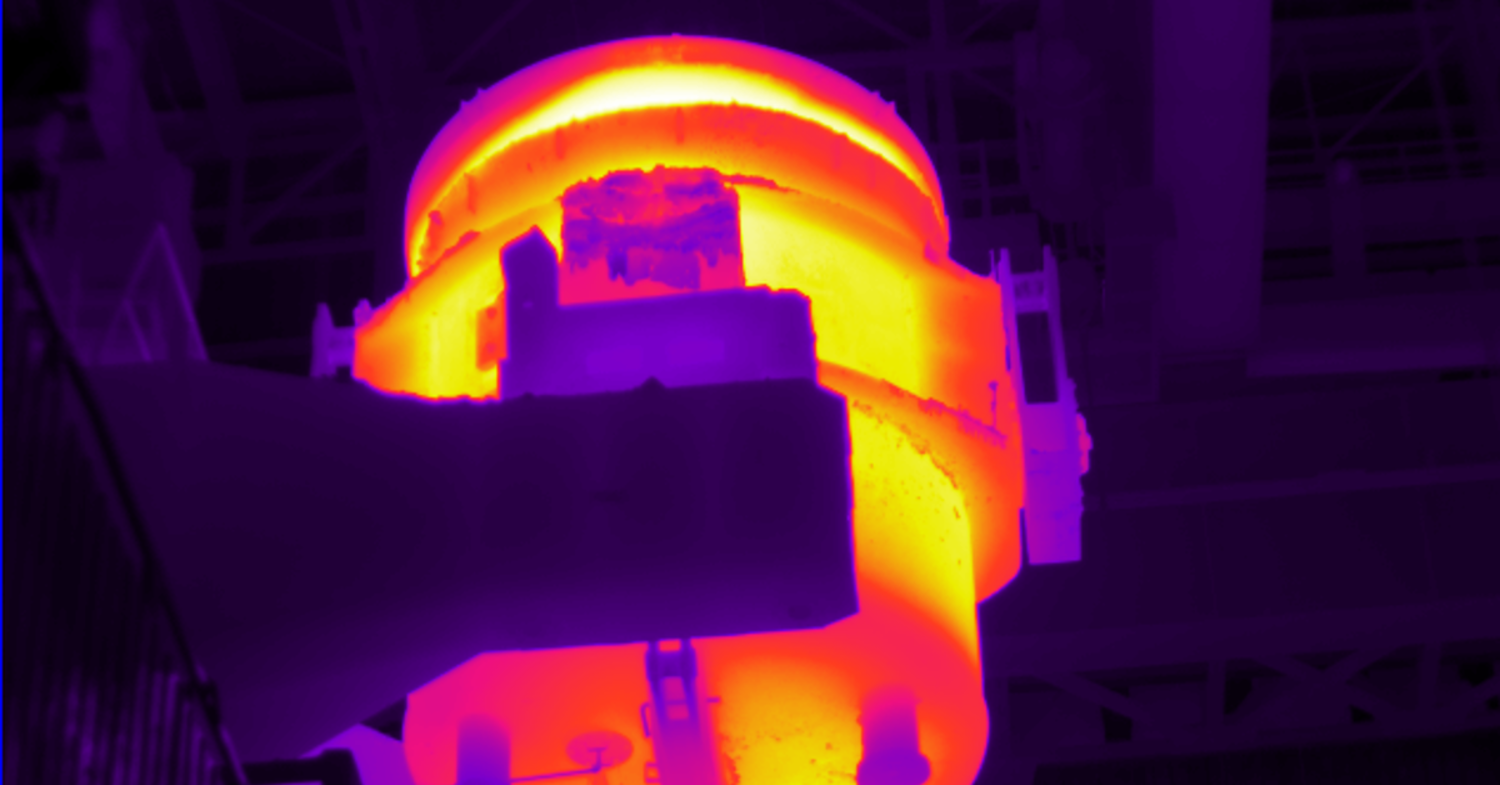

Thermal monitoring solutions are efficiency and safety game-changers for many processes in the steel industry. For instance, steel breakouts threaten the lives of workers and cause unnecessary downtime and significant damage to equipment. This represents just one example of how Viper Imaging uses Teledyne FLIR thermal imaging cameras—monitoring in real-time the health of ladles used to store and transport molten steel—to ultimately prevent a breakout.

In this recorded webinar, Viper Imaging President and Co-Owner, Andy Beck, offers an in-depth look at how Viper Systems interact with FLIR cameras to automate and optimize steel processes with thermal monitoring.

Learn how FLIR thermal imaging cameras in a Viper monitoring system:

• Enable operators to gain insight into their entire process from beginning to end, visibly on-screen and from trending data reports

• Provide critical data in real-time for informed decision-making

• Communicate directly with the plant control system

• Add another layer of safety to your facility and process