Note: For additional Si2-Series support resources, please visit Support.FLIR.com.

FLIR Si2-Series Acoustic Imaging Cameras

Condition Monitoring With a FLIR Si2-Series Acoustic Imager

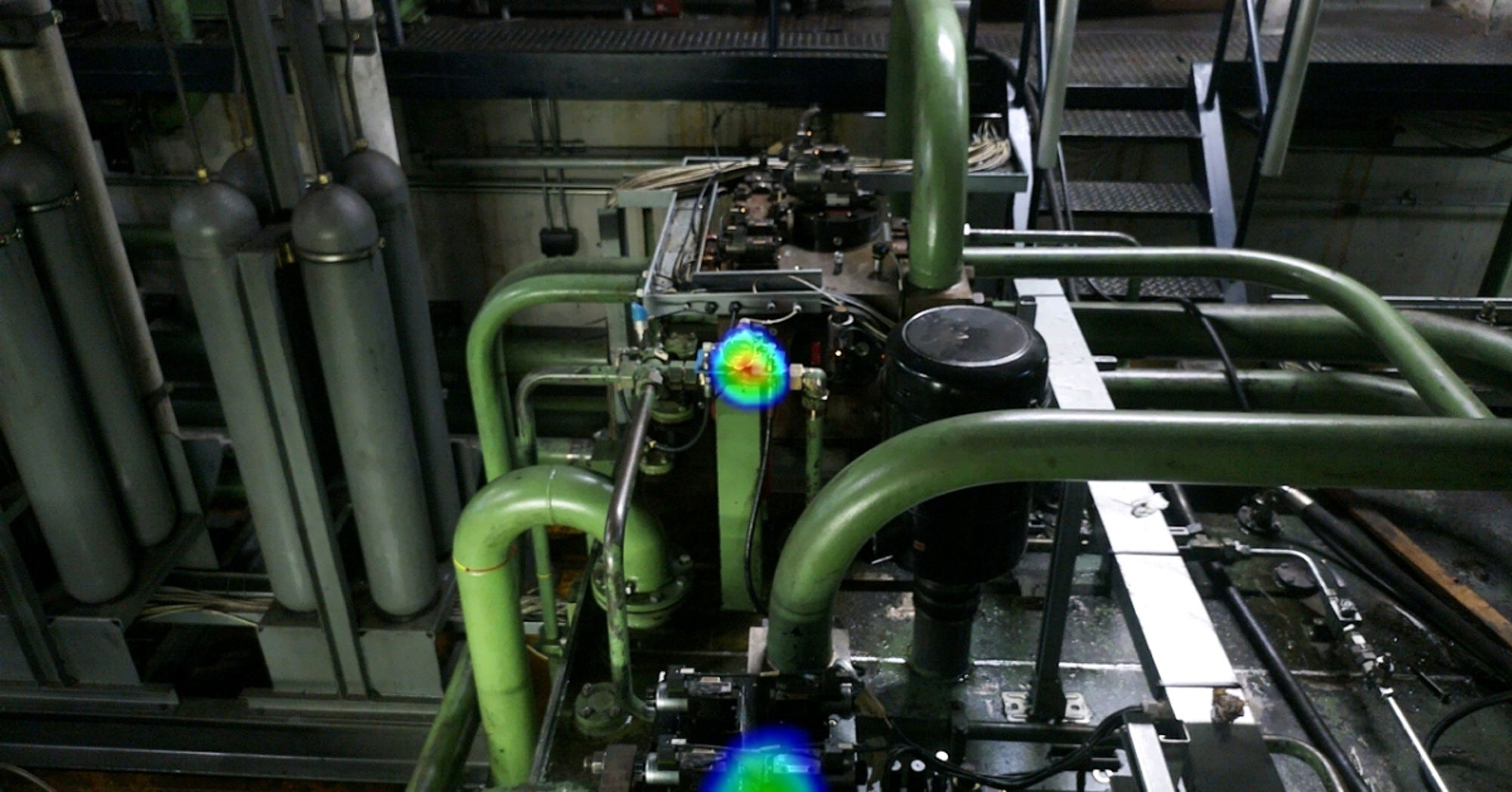

Compressed air leaks, specialized gas leaks, mechanical faults, and electrical partial discharges are all expensive system issues that consume power, leaving your company to deal with unforeseen costs and potential production/uptime issues. Ultrasonic imaging with an acoustic camera is an effective way to detect these equipment issues as part of a complete asset management plan. The FLIR Si-Series is your perfect solution for locating compromised areas in your compressed air systems, and for identifying partial discharge problems in high-voltage electrical systems. This lightweight, one-handed detector can help you in utility, manufacturing, and engineering applications to identify efficiency loss and potential failures up to 10 times faster than traditional methods—with minimal training.

Why Choose a FLIR Acoustic Imager?

Effortless One-hand Operation

You can keep one hand free while inspecting components for operator safety and to reduce neck strain.

Superior Sound Detection with 124 Microphones

Si-Series cameras have 124 microphones, which can help you pick up very quiet noises from a long distance for acoustic imaging. This is especially important when inspecting high-voltage systems and their potential air leaks, which require a safe distance from the energized equipment. The force of a sound signal drops significantly as you move farther away from its source. The solution is to increase the number of microphones: quadrupling the number of microphones essentially doubles the sound detection range. They use optimized dynamic range to balance frequency capabilities with how far sound travels. You want your detectors to use the lowest frequencies possible to get the farthest distance.

Enterprise Scalability

Ensure optimal use and maintenance of equipment in large-scale industrial settings with fleet management, cloud data integration, and OTA software updates. Supporting software also brings the ability to integrate into data historians, reporting options over the cloud and desktop, and combining your IR and acoustic inspection programs. Si-Series users can also take advantage of the Organization feature; a user-friendly solution that simplifies the task of following up the reporting carried out in separate locations by different cameras and users.

Machine Learning Capabilities

The FLIR Si-Series uses machine learning to distinguish the other characteristics of the sound pattern created by leaks and PD from the background. It is the same way you distinguish between a harmonica and a bell playing the same note. Due to the large number of sensitive microphones combined with modern computer processing using machine learning, we are able to distinguish between the background noise and the defect-created noise due to properties other than frequency.

What To Look for In An Acoustic Imager

To ensure you’re choosing the right equipment, take a critical look at your camera’s frequency range. You might think that you need the widest range possible in order to pick up the widest range of sounds. However, in reality, the most effective frequency range for compressed air leak detection is between 20 and 30 kHz. This is because using the 20 to 30 kHz range aids in distinguishing compressed air leaks from the background noise in a factory.

In the pursuit of quieter noises, more is better. Acoustic imaging cameras typically employ dozens of micro-electric-mechanical system (MEMS) microphones to collect and characterize sound. While MEMS are small, use little power, and are very stable, they also generate their own noise that interferes with an individual microphone's ability to pick up very quiet sounds. The solution is to increase the number of microphones in use; simply doubling the number of microphones improves the signal-to-noise ratio enough to remove three decibels of unwanted sounds.

FLIR Thermal Studio Compatibility

The FLIR Si-Series Plugin for FLIR Thermal Studio allows you to import images from FLIR Si-Series acoustic imagers to FLIR Thermal Studio. Easily edit and analyze images, and create advanced reports. With the plugin, you have support for automatic fault classification, severity indication, recommended action for utility inspections, estimation of leak volume, and cost savings for air leaks. Combine acoustic images with thermal imaging from FLIR handheld infrared detectors such as the FLIR E8 Pro for water leak detection in the same report.

Flir Si2-Pro™

From $27590

Acoustic Measurement

124 low-noise MEMS microphones, real-time sound visualization

Severity Assessment

Automatic AI-based severity assessment including recommended actions onboard camera

Distance

From 0.3 m (1.0 ft) up to 200 m (656 ft)

FLIR Si2-PD™

From $20890

Acoustic Measurement

124 low-noise MEMS microphones, real-time sound visualization

Severity Assessment

Automatic AI-based severity assessment including recommended actions onboard camera

Distance

From 0.3 m (1.0 ft) up to 200 m (656 ft)

FLIR Si2-LD™

From $19849

Acoustic Measurement

124 low-noise MEMS microphones, real-time sound visualization

Distance

From 0.3 m (1.0 ft) up to 200 m (656 ft)

Leak Rate

0.0032 l/min from 2.5 m (8.2 ft), 0.0044 l/min from 6 m (19.6 ft)

Acoustic Measurement

124 low-noise MEMS microphones, real-time sound visualization

Acoustic Measurement

124 low-noise MEMS microphones, real-time sound visualization

Acoustic Measurement

124 low-noise MEMS microphones, real-time sound visualization

Severity Assessment

Automatic AI-based severity assessment including recommended actions onboard camera

Severity Assessment

Automatic AI-based severity assessment including recommended actions onboard camera

Distance

From 0.3 m (1.0 ft) up to 200 m (656 ft)

Distance

From 0.3 m (1.0 ft) up to 200 m (656 ft)

Distance

From 0.3 m (1.0 ft) up to 200 m (656 ft)

Leak Rate

0.0032 l/min from 2.5 m (8.2 ft), 0.0044 l/min from 6 m (19.6 ft)

Resources & Support

Datasheet

FLIR Si2-LD Datasheet

- 1

- 2

Chat

Press the chat bubble in the bottom-right corner to connect with us instantly.

(When agents available)

Phone Support

International Line:

(+1) 805 392 3775

Local Number:

(+1) 844 283 5471

Service, Repair and Calibration

Americas

Service Center Contact |

Phone |

Submit an RMA |

Email Us |

|---|---|---|---|

| United States |

Toll Free: (+1) 866 477 3687 Local: (+1) 603 324 7600 |

||

| Canada | 800 613 0507 | Submit an RMA | |

| South & Central America | 0800 878 2486 | ||

Europe |

|||

| Belgium | +32 (0)56 363 041 | ||

| Estonia | +3726063976 | ||

| Germany | +49 (0) 69 95 00 900 | ||

| Italy | +390294753491 | ||

| Sweden | +46 (0) 8 753 26 54 | ||

| United Arab Emirates | +971 4 802 4999 | ||

| United Kingdom | +44 (0)1732 220 011 | ||

Asia Pacific |

|||

| Australia | +61 (0) 3 9550 2800 | ||

| China | +86 (0) 21-5169-7628 | ||

| India Delhi | +91 11 47212002 | ||

| India Faridabad | +91 (129) 431-5031/32 | ||

| Japan | 81-3-6721-6648 | ||

| Singapore | +65 8787 0884 | ||

| South Korea | (02)565-2724 | ||